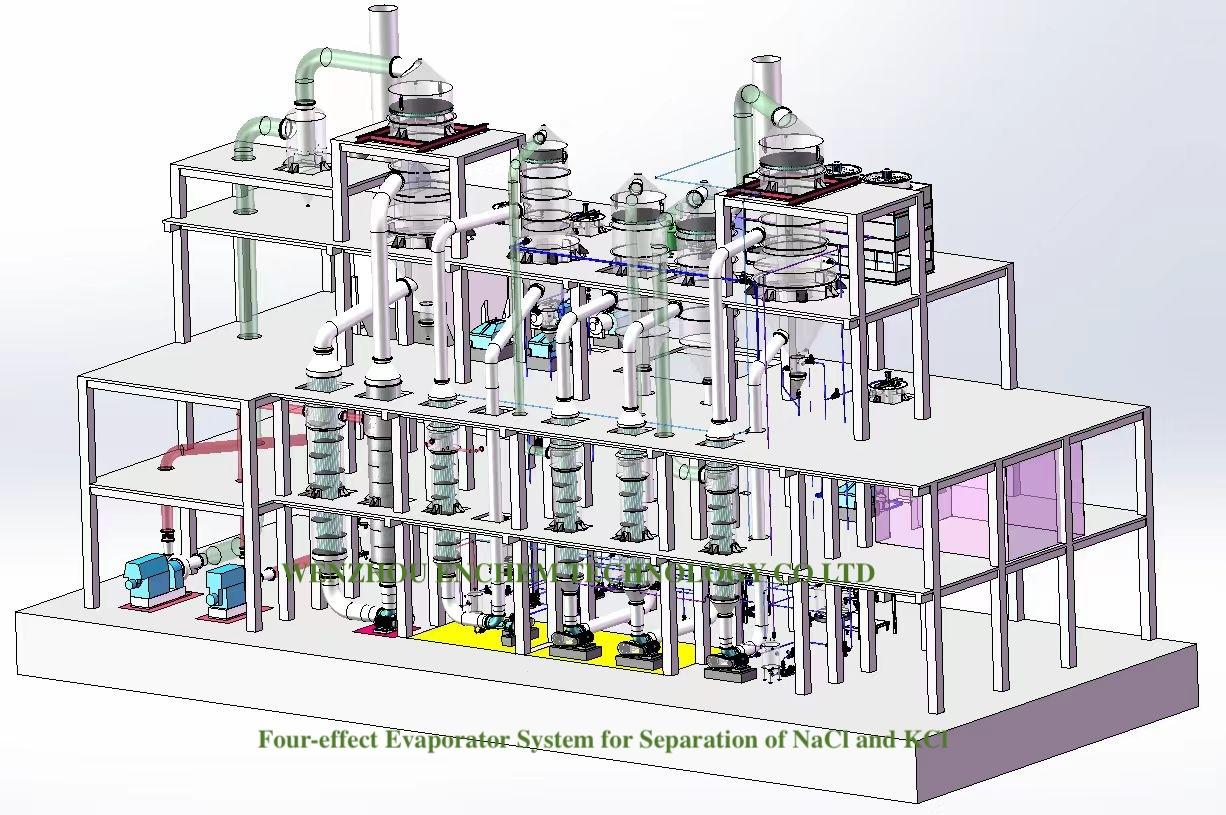

Potassium-Sodium Separation Evaporator

Project description: Potassium-sodium separation evaporator ;

Equipment: Four-effect forced circulation evaporator combined with cooling crystallization;

Main composition of feedstock: potassium-sodium mixed liquid;

Evaporation capacity: 50,000L/h;

Construction material: product wetted parts adopt TA2, non wetted parts adopt SS 304 or carbons steel per actual need.

Advantage: Transform waste into value—optimize your high-salinity wastewater treatment with advanced potassium-sodium separation technology.