MVR Evaporator Overview

MVR (Mechanical Vapor Recompression) evaporator is a high-efficiency, energy-saving evaporation system that recycles the latent heat of secondary vapor through mechanical compression.

During the evaporation process, secondary vapor generated from the feed is mechanically compressed by a vapor compressor. This compression increases the vapor’s temperature, pressure, and enthalpy, enabling it to be reused as a heating medium in the heat exchanger for incoming feed material.

By fully utilizing the latent heat of vaporization, the system significantly reduces the need for external steam. After startup, only a small amount of fresh steam is required to maintain continuous operation.

Multi-Effect Evaporator Overview

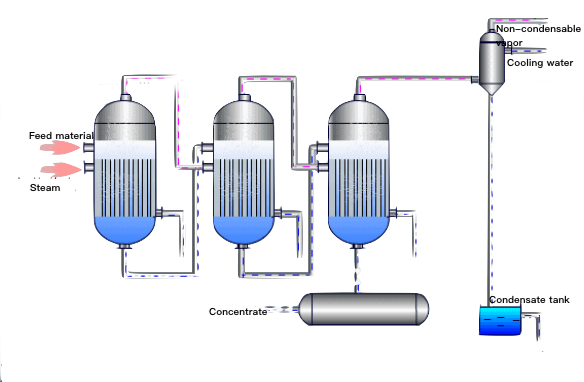

Multi-Effect Evaporator (MEE) is an evaporation system that connects multiple evaporator stages—referred to as “effects”—in series. The secondary vapor produced in one effect is used as the heating medium for the next, progressively utilizing thermal energy across multiple stages.

The primary advantage of using a multi-effect evaporator is the significant reduction in fresh steam consumption, making it a highly effective method for conserving thermal energy in industrial evaporation processes. Among various multi-effect designs, the triple-effect evaporator is the most widely used configuration in industrial applications.

MVR vs. MEE: Operating Cost Comparison

The MVR evaporator primarily consumes electricity to drive the vapor compressor. The secondary vapor generated during evaporation is mechanically compressed to increase its temperature and pressure, allowing it to be reused as the heating medium. Only a small amount of live steam is required during startup and as a supplement during operation.

In contrast, the multi-effect evaporator (MEE) relies on a continuous supply of live steam as the primary heat source. It transfers heat from one effect to the next, but still requires a significant amount of fresh steam to maintain effective evaporation performance.

In terms of energy efficiency, MVR evaporator systems have a clear advantage—especially in large-scale, continuous operations—where long-term electricity costs may be lower than the steam cost of a MEE system, depending on local electricity-to-steam pricing.

However, the two technologies are not direct substitutes. The optimal selection should be based on material characteristics, process requirements, and local utility conditions to meet the demands of complex operating conditions.

The table below provides a general comparison of the operating costs between MVR evaporator and a typical triple-effect evaporator. Actual values will vary depending on specific project conditions and utility prices.

|

Item |

Triple-effect evaporator | MVR Evaporator | |

|

Evaporation capacity:16ton/hr |

|||

|

Operating mode |

Floor area (m) | 12 *18 | 6 *12 |

|

Energy sources |

Fresh steam |

IEI |

|

| Material input/output | Continuous |

Continuous |

|

|

Operating cost |

Steam (t/h) | 6.6 | 0.9 |

|

Power consumption (kwh) |

~240 |

~923 |

|

| Circulating water (m3/h) | 600 |

100 |

|

| Note: The above power consumption includes the energy used by the centrifuge, thickener agitators, and other auxiliary equipment. | |||

Contact Us

Feel free to contact us for customized solutions and competitive offers in evaporation and crystallization systems.