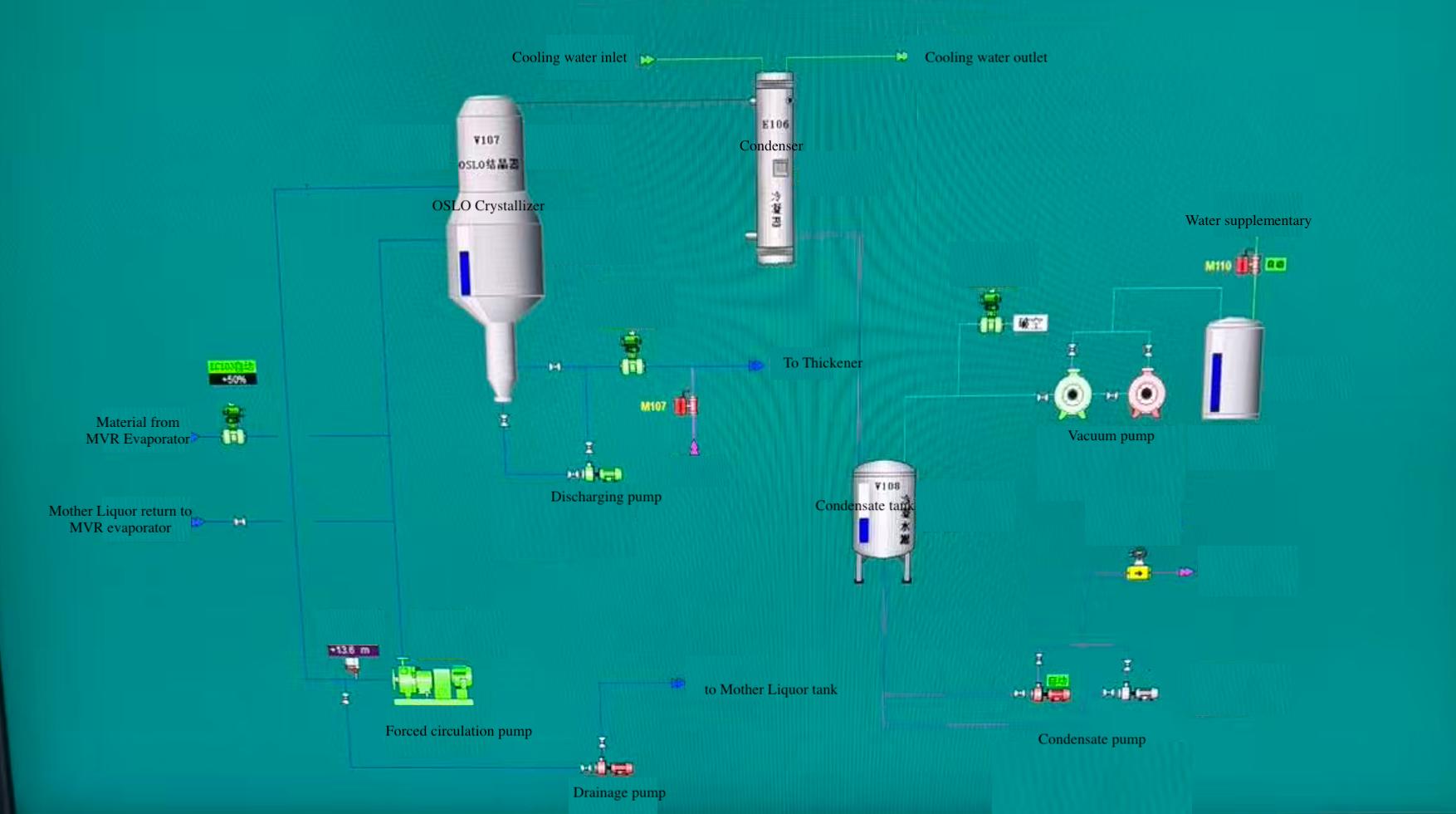

Battery-Grade Nickel Sulfate Hexahydrate Evaporation & Crystallization Plant

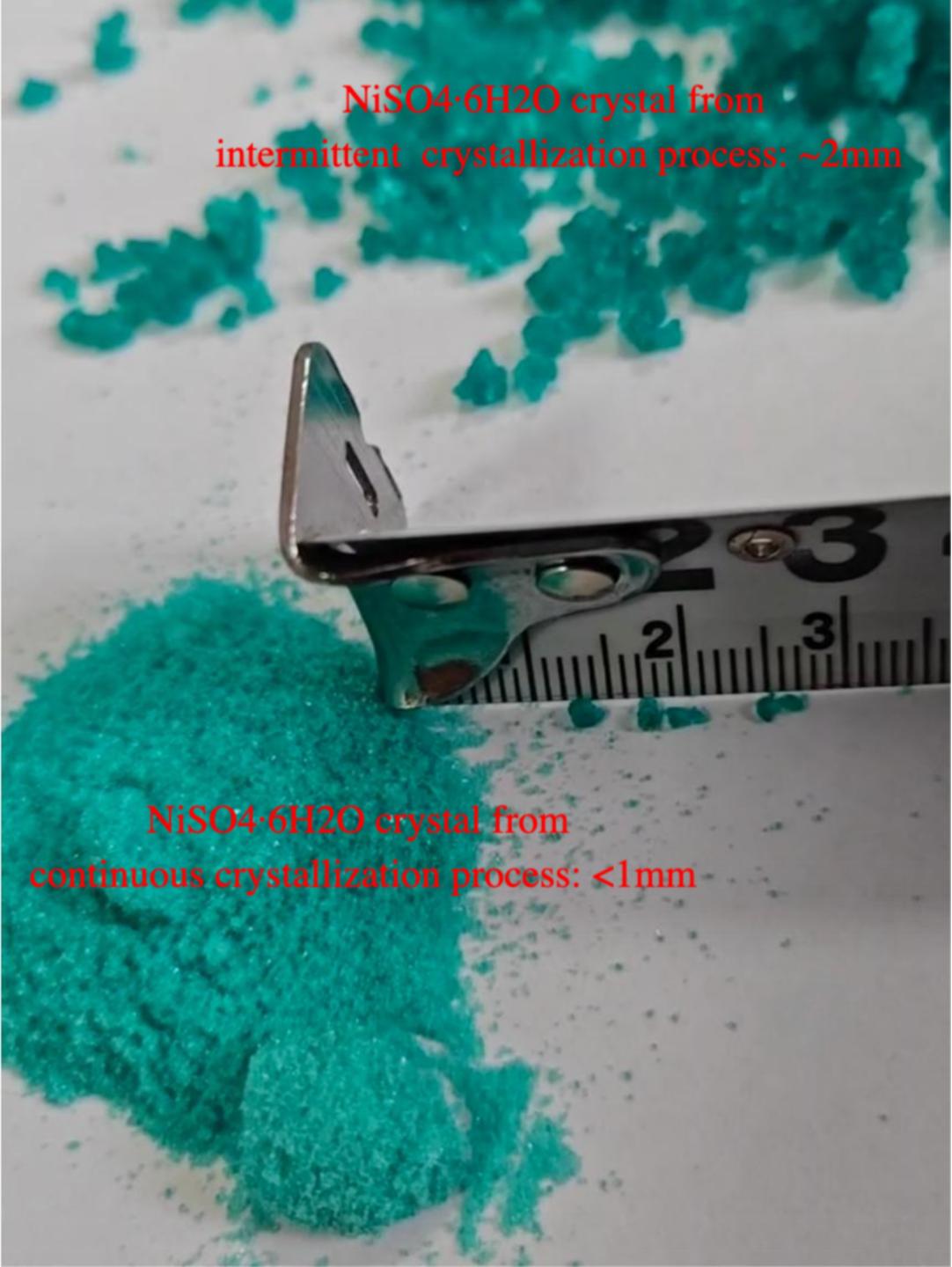

Project description: Evaporation and crystallization system designed for the production of high-purity, battery-grade nickel sulfate hexahydrate (NiSO₄·6H₂O).

Application: the system is suitable for battery raw material production as well as recovery and recycling of nickel from spent batteries, providing a flexible solution for both primary production and sustainable resource recovery.

Project scale: The system can be fully customized based on production capacity and specific client requirements, offering a flexible solution tailored to your needs.

Construction material: product wetted parts adopt TA2, non wetted parts adopt SS 304 or carbons steel per actual need.