Overview

We are pleased to announce that the Potassium-Sodium Separation Four-Effect Evaporator System, engineered and delivered by our company, has been successfully commissioned and is now operating stably.

Following a period of rigorous installation, fine-tuning, and trial runs, the system has achieved continuous and reliable performance, marking a significant milestone in our ongoing efforts to advance high-salinity wastewater treatment and potassium-sodium separation technologies.

Project Information

In industrial production, large volumes of wastewater containing both potassium and sodium are generated daily. Traditionally, this mixture—primarily potassium chloride (KCl) and sodium chloride (NaCl)—is treated as industrial solid waste. However, separating these two salts creates considerable economic value, particularly through the recovery of high-purity potassium chloride.

The separation of potassium chloride from sodium chloride leverages their distinct solubility behavior: potassium chloride’s solubility increases significantly with rising temperature, while sodium chloride’s remains relatively stable.

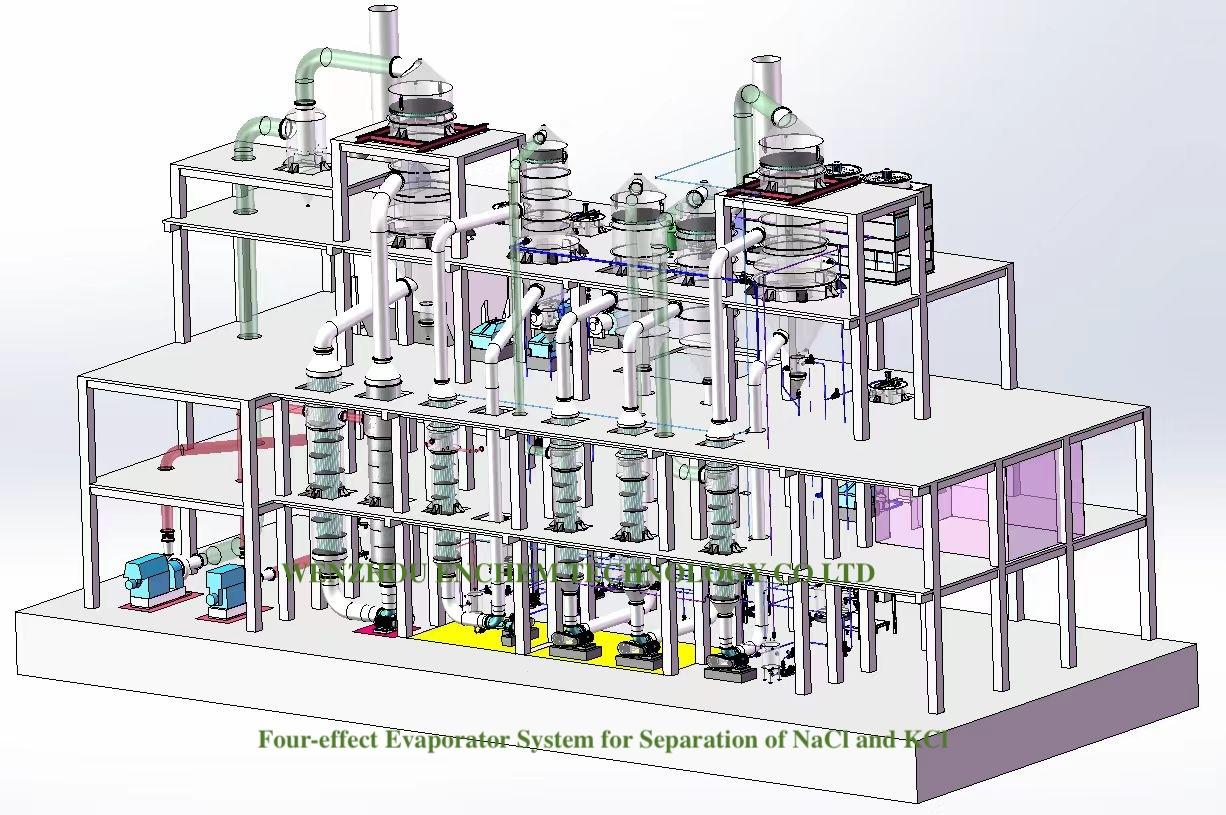

This project employs a four-effect evaporation process, tailored to the feed composition and production capacity.

• In the first effect, sodium chloride reaches saturation and crystallizes out.

• The supernatant—enriched in potassium chloride—moves through successive effects for further evaporation.

• In the fourth effect, potassium chloride reaches supersaturation, precipitates, and is collected.

The result is the efficient recovery of high-purity sodium chloride and potassium chloride, turning waste into valuable, reusable products.

System Highlights

This four-effect evaporator system features an advanced multi-effect evaporation process optimized for the unique physical and chemical characteristics of potassium chloride and sodium chloride. The system not only ensures efficient thermal energy utilization but also delivers high-performance separation, enabling the recovery of high-purity sodium chloride and potassium chloride from wastewater, effectively transforming waste into valuable resources.

• Outstanding energy efficiency – significantly reduced steam consumption via integrated four-effect design

• Excellent separation performance – consistent achievement of target purity and product yield

• High level of automation – reliable and user-friendly control system ensures stable operation

•Environmentally sustainable – enables the recovery of high-value potassium chloride from mixed salts, maximizing resource utilization and minimizing waste

The successful startup of this system reflects the dedication, expertise, and coordination of our entire project team and partners. It also marks another important step forward for our company in the field of advanced separation technology and high-efficiency process systems.

Get In Touch With US

Enchem is here to listen to your needs and provide sustainable solutions. Contact us to discover more.