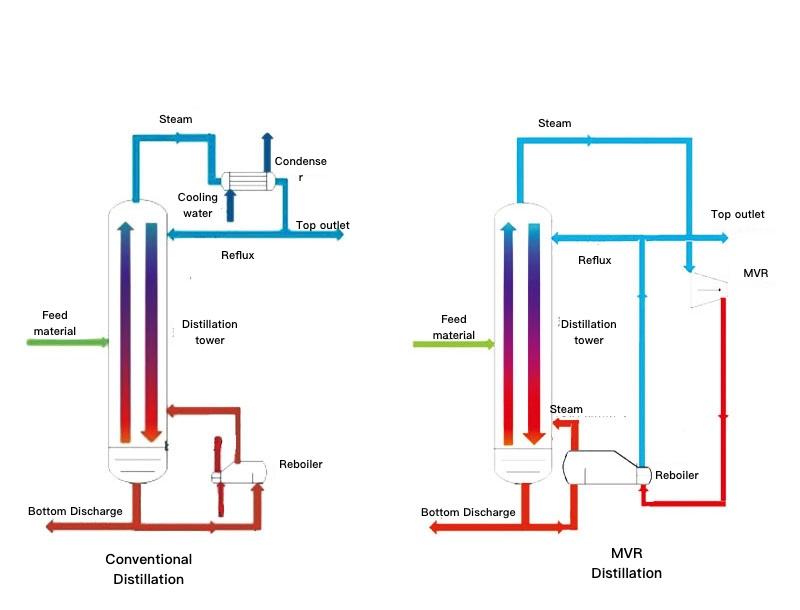

MVR Distillation Technology

The MVR (Mechanical Vapor Recompression) distillation system compresses the low-temperature vapor from the top of the distillation column using a steam compressor, increasing its temperature and pressure. The compressed vapor then enters the reboiler, where it condenses and transfers heat to the bottom liquid, thus maintaining the energy balance of the distillation process solely through mechanical compression.