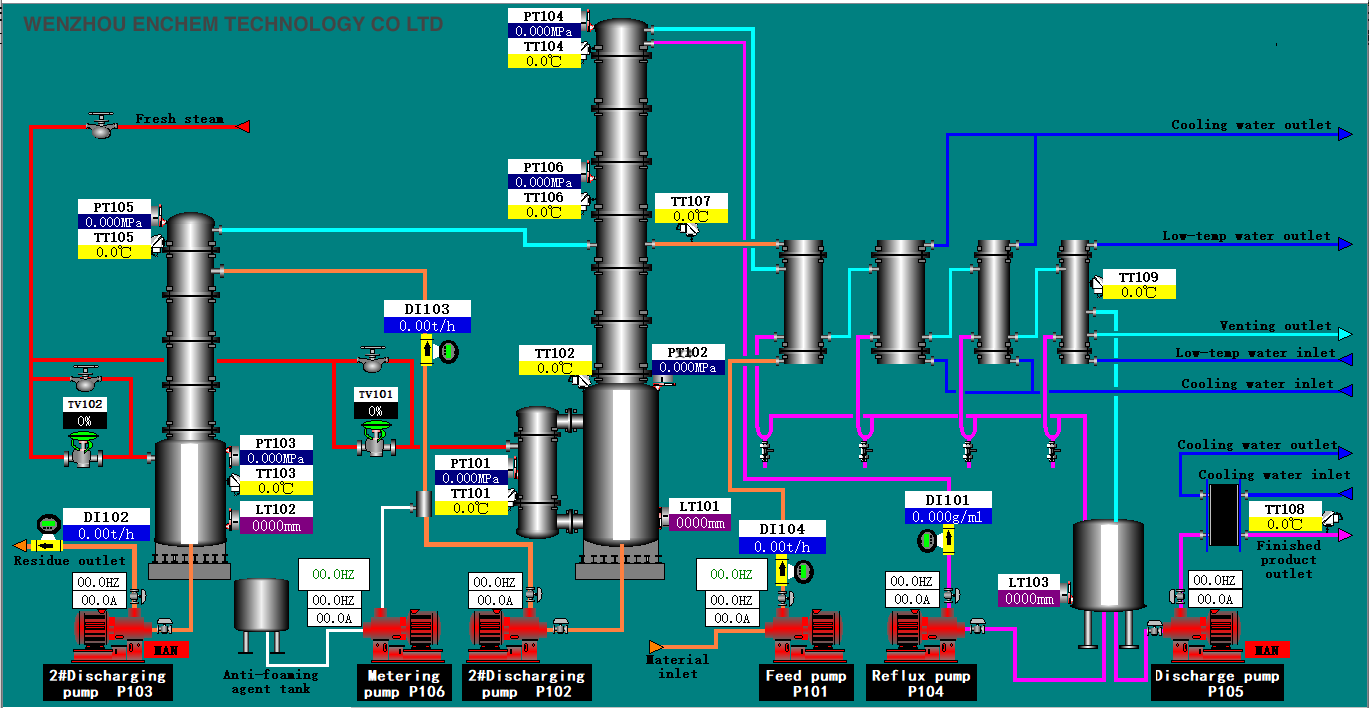

Ethanol Recovery System (Ethanol recovery from waste liquid soap)

An ethanol recovery system, recovers ethanol from waste liquid soap and distills it to 95%. This initiative not only minimizes waste production but also creates certain economic value by recovering valuable products from waste.

Treatment capacity: 1200L/hr;

Input ethanol content: 65%;

Output ethanol content:95%.