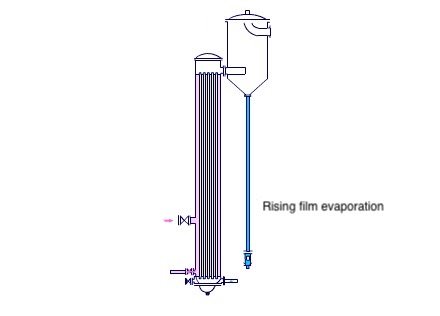

Principle and improvement of rising film evaporator

Principle of rising film evaporator

Once there was a strange phenomenon in a factory: there was one vertical evaporator and one horizontal evaporator, the vertical one was about half the volume of the horizontal one, but evaporation efficiency of the vertical one was significantly better than the horizontal one under same condition. And the rising film evaporator happens to be a vertical evaporator.

The evaporation efficiency of the evaporator is in direct proportion to its heat transfer efficiency, so to understand the principle of the rising film evaporator shall start from its internal heat transfer mechanism. For rising film evaporator, evaporation happens in the heating tube, and it is generally divided into 6 stages: 1. preheating stage; 2. bubble generation stage; 3. emulsification stage; 4. conversion stage; 5. film forming stage, and; 6. steam stage.

Since in the steam stage, the evaporation has been finished, it is not considered. From 1st stage to 5th stage, the heat transfer efficiency is from low to high, and it is highest in the 5th stage (film forming stage) . Because the rising film evaporator has a film forming stage, the evaporation efficiency is greatly improved.

Why is the heat transfer efficiency the highest when the material flowing in thin film state ? Because the thickness of the boundary layer is greatly reduced, and the thermal resistance is greatly reduced.

Improvement of rising film evaporator

From the above discussion, it is known that flowing in thin film is the key to the rising film evaporator. So the improvement of the evaporation efficiency of the rising film evaporator, shall start from it.

Let’s study the conditions of the film forming, how can transform the raw liquid into film state?

1. There should be a certain amount of vapor presenting. Obviously, the film is blown out by the vapor, which could not be realized by small amount of vapor, for example, no film flowing in 1st , 2nd and 3rd stage.

2. The film is formed only in case the gas-liquid ratio is within a certain range.

3. The film is formed when the flow of gas and liquid are in the same direction. Otherwise, no liquid film would be formed.

4. The film is formed when the gas flow rate exceeds a certain range.

5. The film is formed when the liquid flow rate exceeds a certain range.

In conclusion, the improvement of the evaporation efficiency of the rising film evaporator are:

1. Create gas as earlier as possible, to shorten the formation time of film as far as possible.

2. Control the amount of material liquid into the evaporator, so that the gas-liquid ratio enters the film forming range as soon as possible.

3. The liquid has a downward tendency because of its own weight, so from this point of view, the falling film evaporator is more conducive to film formation.

4. The control of the flow rate, which can be improved by design.

Contact Us

Reach out to an optimized proposal