Overview

When classifying crystallizers based on the circulation mode of the material, the most common types include external circulation crystallizers, DTB (Draft Tube Baffle) crystallizers, and OSLO crystallizers.

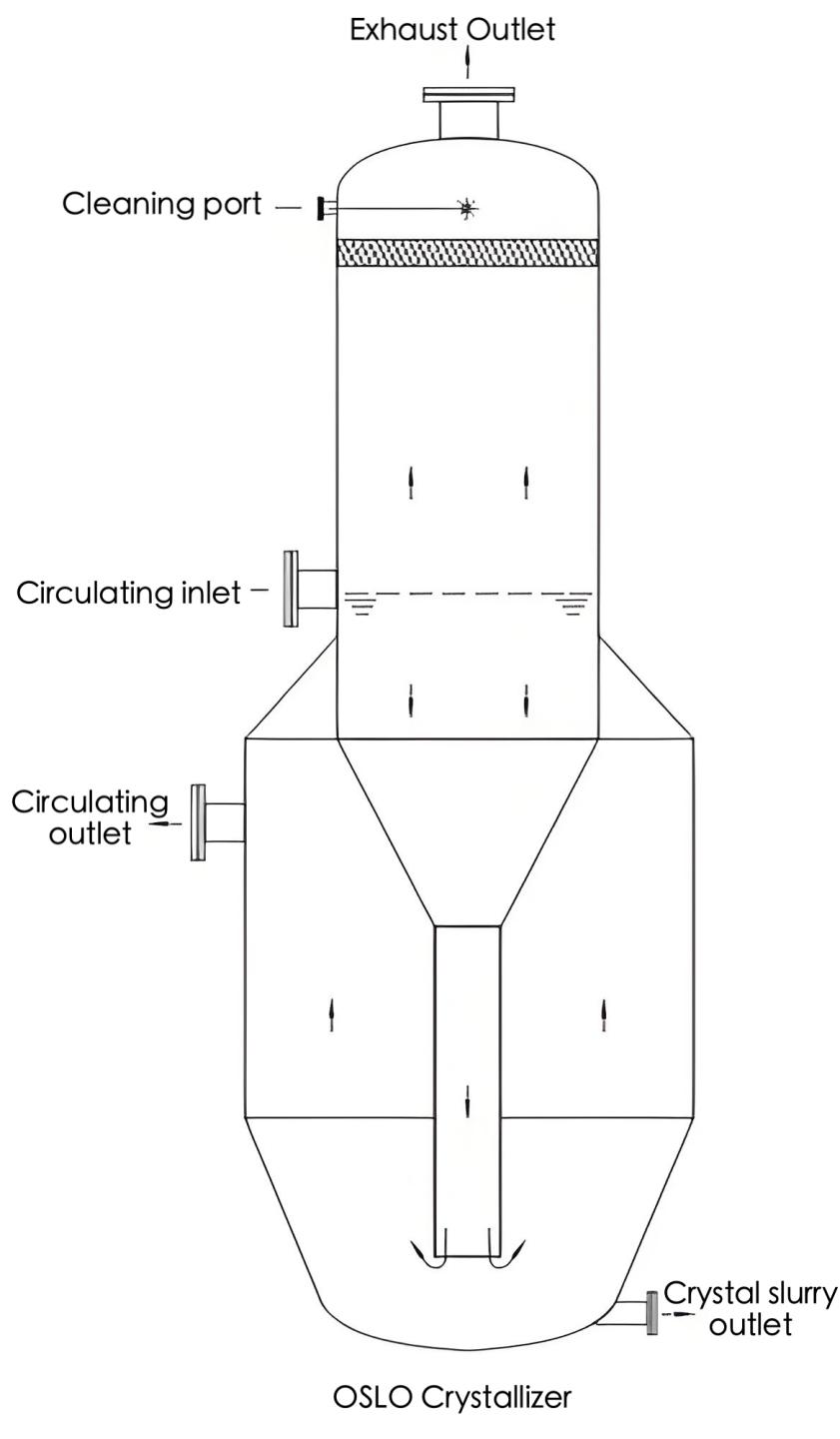

The OSLO crystallizer—also known as the suspension bed crystallizer or Krystal crystallizer—is designed for applications where large, spherical, and uniform crystals are required. It operates based on a fluidized crystal bed, in which crystals are suspended and grown under carefully controlled supersaturation conditions.

Typical Components

• Evaporation (or cooling) chamber: Where mother liquor reaches supersaturation through evaporation or cooling.

• Crystal fluidized bed: Supersaturated mother liquor enters from the bottom, fluidizing crystal particles and allowing solute deposition on their surfaces.

• Circulation system: The mother liquor is recirculated by a pump to maintain the loop.

Working Cycle

• The circulation pump draws clear solution with little to no crystals and sends it to the heater.

• Heating increases the supersaturation of the mother liquor.

• The heated solution is fed into a central downpipe that extends deep into the lower fluidized bed zone.

• As the solution slowly rises through the crystal bed, supersaturation decreases and solute deposits on crystal surfaces.

• Crystals are graded automatically from bottom to top by size. The bottom has larger product crystals; the top contains undersized ones.

• Near the pump inlet, the solution is nearly clear, ensuring only liquid is recirculated.

• Product crystals are withdrawn from the bottom, ensuring uniform, spherical, and coarse crystal output.

Operational Features

• Counter-current contact of supersaturated solution and crystal particles allows even crystal growth and narrow size distribution.

• Adjustable circulation rate makes it easy to control supersaturation and minimize secondary nucleation.

• The design provides excellent product crystal uniformity but has some operational constraints:

– Supersaturation must remain within a narrow metastable zone.

– The production capacity is lower than slurry-circulation types for the same vessel size due to limits in fluidization velocity and slurry concentration.

Application Scenarios

The OSLO crystallizer is best suited for applications requiring large, high-purity crystals, such as:

• Potassium chloride (KCl)

• Sodium sulfate (Na2SO4)

• Other inorganic salts

Conclusion

The OSLO crystallizer is a highly effective solution for producing large and uniform crystals, especially when downstream processing or product specifications demand precise control over size and shape. While its throughput may be lower than slurry-based systems, its excellent product quality makes it a preferred choice in many chemical and salt production applications.

Get In Touch With US

Enchem is here to listen to your needs and provide sustainable solutions. Contact us to discover more.