What is MVR (Mechanical Vapor Recompression)?

MVR is the abbreviation for Mechanical Vapor Recompression. It is an energy-efficient evaporation technology that recycles the latent heat of vaporized steam.

In a MVR Evaporator system, a mechanical compressor compresses the secondary vapor generated during evaporation. This process raises the vapor’s pressure, temperature, and enthalpy (thermal energy content). The recompressed vapor is then redirected to the heating chamber of the evaporator, where it serves as the primary heat source for further evaporation of the incoming feed liquid.

By continuously recycling the vapor’s thermal energy, MVR evaporator systems drastically reduce the need for external steam input, resulting in significant energy savings and lower operating costs.

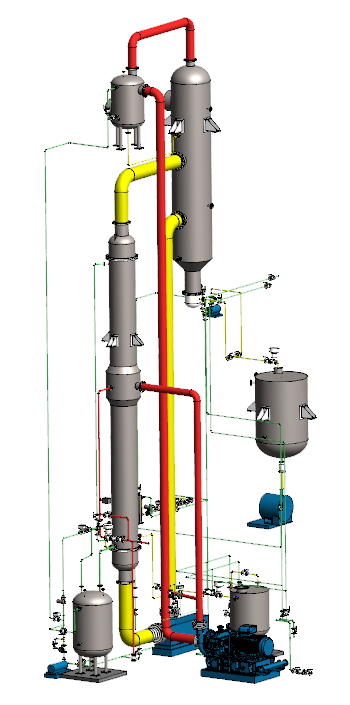

Main Component of a MVR Evaporator

MVR Vapor Compressor: Mechanically compresses secondary vapor to increase its pressure and temperature and consequently its enthalpy, enabling it to be reused as the primary heat source in the evaporator.

Heat Exchanger: Transfers heat from the compressed vapor to the feed material.

Vapor–Liquid Separator: Separates vapor and liquid phases after evaporation.

Secondary Separator: purifies the vapor by removing entrained droplets, ensuring high-quality vapor enters the MVR compressor.

Thickener: facilitates increased solids crystallization by reducing the temperature of the concentrated solution, promoting supersaturation and crystal formation.

Condensate Tank: Collects condensed water (distillate) from the vapor.

Centrifuge: Separates solid crystals from the liquid phase.

Mother Liquor Tank: Stores the residual liquid phase after centrifuge.

Circulation Pump and Other Pumps: Maintain fluid movement throughout the system.

Automation System: Enables centralized control, monitoring, and process optimization.

Applications of MVR Evaporator

The widespread application of MVR (Mechanical Vapor Recompression) evaporators is primarily driven by their exceptional energy-saving performance. By recycling the latent heat of vapor through mechanical compression, MVR evaporator systems drastically reduce steam consumption and operational costs, making them ideal for large-scale, continuous evaporation and crystallization processes.

Typical Application Industries:

– Fine Chemicals and Pharmaceuticals

– Petrochemical Industry

– Solid and Hazardous Waste Treatment

– RO Concentrate Treatment

– Treatment of desulfurization wastewater in Power Plants

– Food and Beverage Industry

-New Energy and Lithium Battery Industry

– Electronics and New Materials

– Environmental Engineering

Contact Us

Feel free to contact us for customized solutions and competitive offers in evaporation and crystallization systems.