Overview

When classifying crystallizers based on the circulation mode of the material, the most common types include external circulation crystallizers (FC type), DTB (Draft Tube Baffle) crystallizers, and OSLO crystallizers.

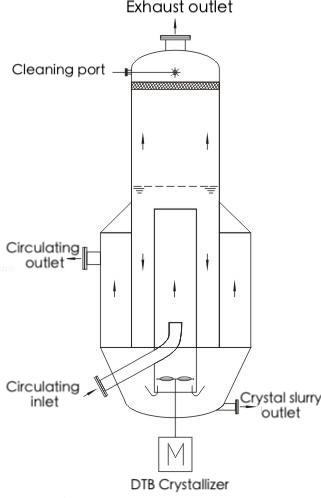

The DTB (Draft Tube Baffle) crystallizer is a high-performance internal circulation crystallizer designed for applications requiring large, uniform, and high-purity crystals. With its precise control of supersaturation and integrated classification mechanism, the DTB crystallizer is widely used in food, pharmaceutical, and fine chemical industries.

Structure and Working Principle

Core Components:

• Draft Tube: Centrally positioned in the crystallization chamber, it directs the upward flow of slurry, forming a strong forced circulation.

• Annular Baffle Plate: Creates an outer settling zone that allows larger crystals to settle, while smaller crystals and mother liquor continue to circulate, facilitating effective particle size classification.

• Vacuum Evaporation or Cooling System: Induces supersaturation through solvent evaporation or temperature reduction.

• Elutriation Column: Located at the bottom, it uses hydraulic classification to separate product-size crystals from fines.

Working Cycle:

1 – Thermally saturated feed is continuously introduced at the bottom of the circulation pipe.

2 – The feed mixes with mother liquor containing fine crystals and is pumped through a heater.

3 – The heated solution enters the bottom of the draft tube and is circulated upward by a slow-speed propeller.

4 – Supersaturation occurs near the liquid surface via evaporation or cooling, causing crystal growth on suspended particles.

5- Larger crystals settle in the annular zone outside the baffle, while fines re-enter the circulation loop for further processing or dissolution.

6- Crystals at the crystallizer bottom enter the elutriation column, where undersized crystals are returned, and qualified product crystals are discharged.

Operational Features

• Uniform supersaturation and stable growth environment support the production of large crystals (600–1200 µm).

• Efficient crystal classification via the annular baffle and elutriation column reduces fines and improves product quality.

• High productivity and low scaling risk enable long-term continuous operation.

Application Scenarios

The DTB crystallizer is ideal for industries requiring consistent, coarse crystals with high purity:

• Food Industry: Sucrose and other sweeteners

• Pharmaceuticals: Antibiotics and specialty APIs

• Inorganic Chemicals: Potassium nitrate, ammonium sulfate, citric acid

Conclusion

The DTB crystallizer offers excellent control over crystal size distribution and product purity. Its robust internal circulation design and integrated classification system make it a preferred solution for demanding crystallization processes across various industries.

Get In Touch With US

Enchem is here to listen to your needs and provide sustainable solutions. Contact us to discover more.