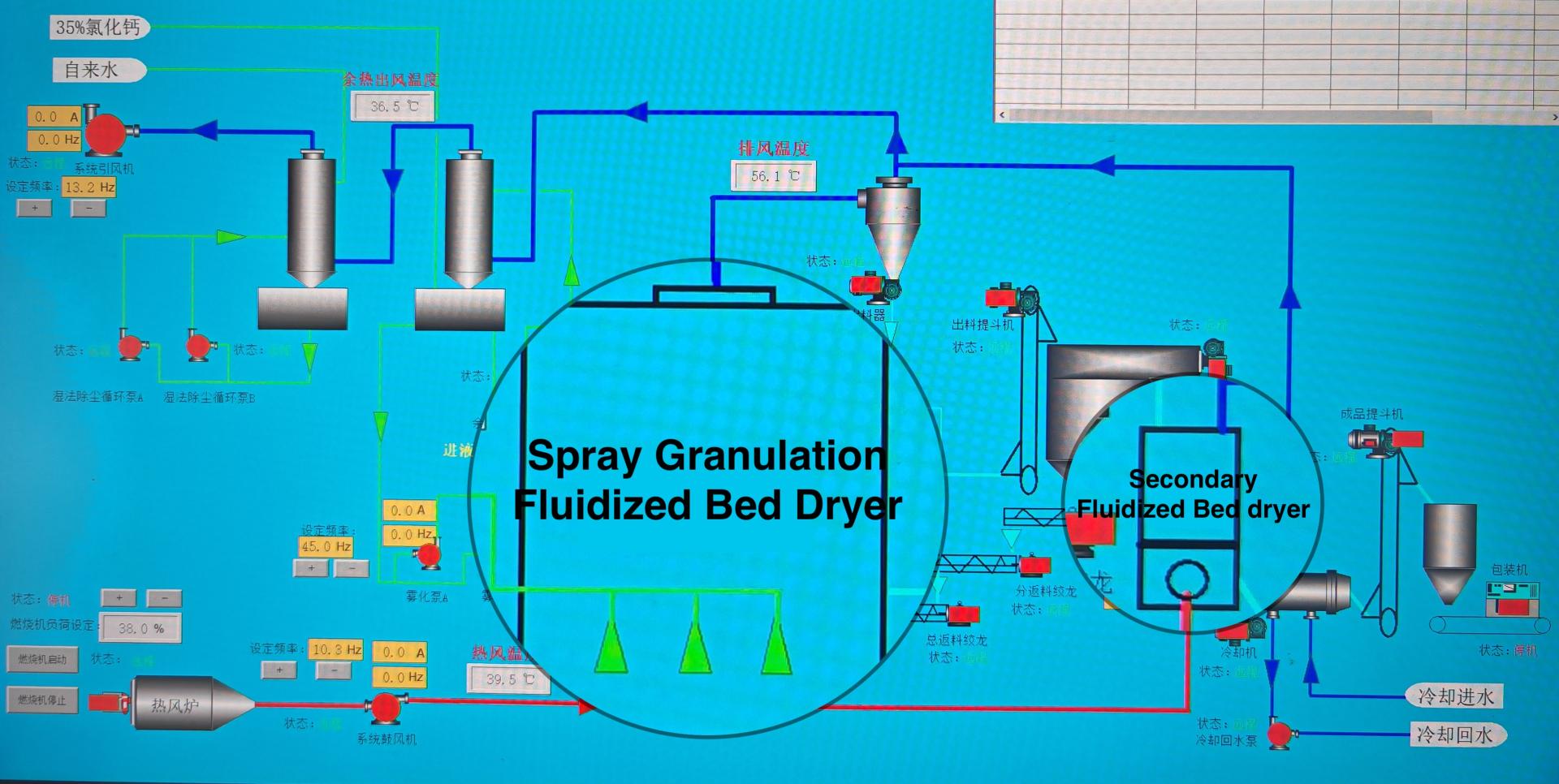

Unlike conventional spray granulation fluidized bed dryers for granulation and drying of calcium chloride, our design incorporates a secondary fluidized bed after the main granulation fluidized bed dryer. This added stage delivers significant advantages in product quality, energy efficiency, equipment investment and operational stability.

Improved Product Yield and Consistency

In a conventional single-stage granulation and fluidized bed dryer system, calcium chloride granulation and drying occur in one fluidized bed dryer. After screening:

• ~2/3 of material is rejected and recycled due to inappropriate particle sizes;

• Only ~1/3 qualifies as finished product and moves to the cooling stage.

However, not all the qualified material that enters the cooling unit reliably meets the required final moisture specification, leading to variability in product quality.

With a secondary fluidized bed:

• Only pre-qualified product enters the secondary fluidized bed dryer

• Final moisture content is consistently achieved before cooling

• Product quality is stabilized

Reduced Energy Consumption and Equipment Investment

In a single-stage set-up, the main dryer must handle 100% of the drying load, both the recyclable (2/3) and final product (1/3). To ensure all material meets moisture targets, the dryer must be:

• Larger in size, increasing capital costs

• Higher in drying temperature, increasing energy consumption;

• More complex, producing more exhaust gas and requiring more infrastructure

With a secondary fluidized bed:

• The second-stage dryer only handles the 1/3 of already qualified product

•The main dryer can be smaller and more efficient

• Energy use and heat load are reduced

• Exhaust gas volume is lower

• Overall system investment is significantly optimized

Improved System Stability

In a single-stage spray granulation fluidized bed, one way to ensure the discharged product meets moisture requirements is by increasing the exhaust air temperature. However, this approach has serious drawbacks:

The Problems with High Exhaust Temperatures:

• Less droplet adhesion during atomization = more dust

• Excess dust disrupts granulation and reduces yield

• Dust overloads cyclone separators and wet scrubbers

• Backpressure increases, leading to frequent clogs

• More downtime and cleaning—reduced uptime and efficiency

By adding a secondary fluidized bed, the main dryer can operate at a lower exhaust temperature, avoiding these issues entirely.

Advantages include:

• Greater system stability

• Fewer shutdowns for maintenance

• More consistent and continuous production

Conclusion: Smarter, More Sustainable Drying

Integrating a secondary fluidized bed into the calcium chloride spray granulation fluidized bed dryer process delivers significant, multi-dimensional benefits:

• Higher product quality and consistency

Ensures all final product meets moisture specifications, reducing rework and improving yield.

• Lower energy consumption and equipment investment

Drying only the qualified portion reduces heat demand, equipment size, and operating costs.

• Improved system stability and uptime

Lower operating temperatures reduce dust formation and system fouling, enabling longer continuous operation.

• More environmentally friendly operation

Lower energy use means reduced carbon emissions.

Less exhaust and dust generation minimizes air pollution and eases the burden on dust removal systems.

In short: This upgraded design is not only more efficient and reliable—it’s also a more sustainable solution for modern chemical drying applications.

Contact US

Feel free to contact us for customized solutions and competitive offers for calcium chloride system