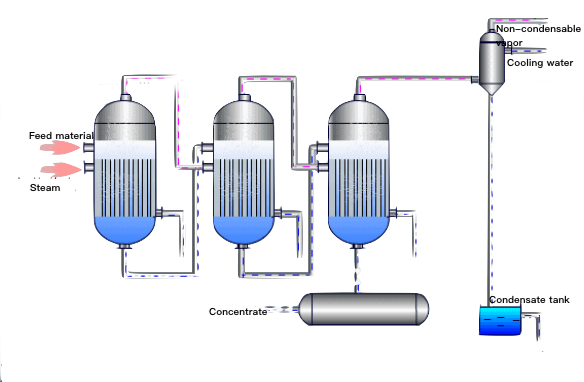

Multiple-effect Evaporator (MEE)

A multiple-effect evaporator is a combination of multiple sets of evaporator stages or effect, the core principle is utilizing the secondary steam generated by the evaporation in the previous effect as the heat source for the next effect to achieve the purpose of saving energy.