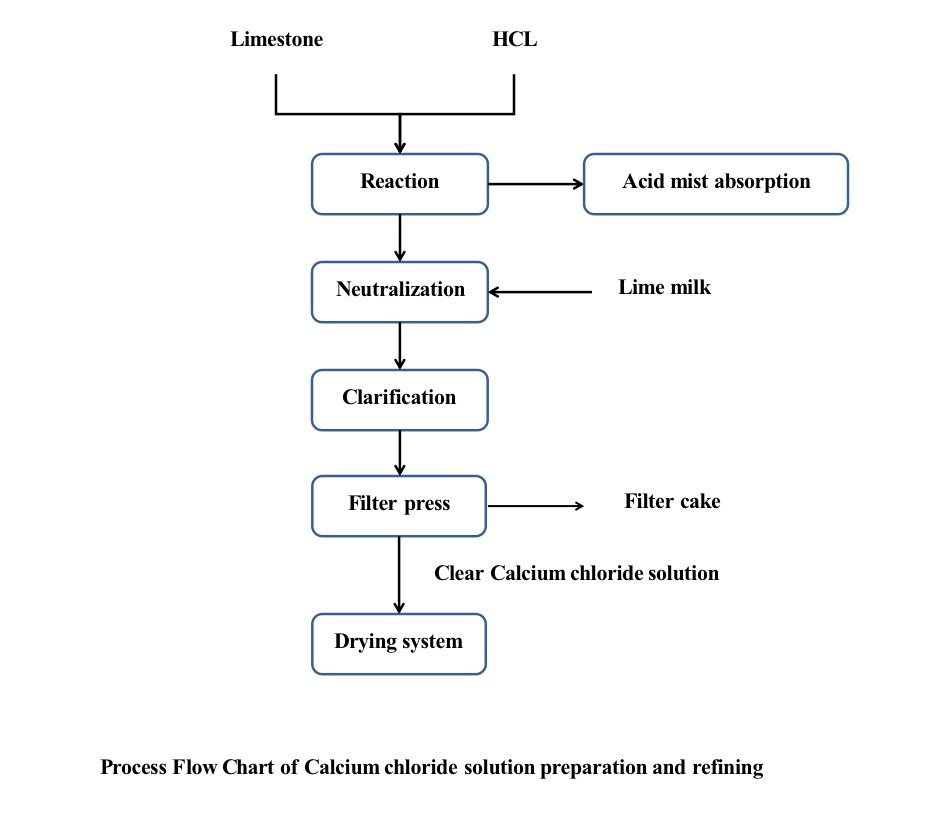

Calcium Chloride Solution Preparation and Refining Plant

Calcium chloride solution preparation and refining system:

1.the raw material are hydrochloric acid and limestone or acetylene sludge, and;

2.the plant consists of limestone feeding system, multiple-stage reactor, acid mist absorption tower, lime milk preparation system, neutralization pond, clarification pond, filter press and finished calcium chloride liquid buffer pond.