WENZHOU ENCHEM TECHNOLOGY CO LTD was established in 2012, and is a high-tech enterprise specializing in the process design and manufacturing of system equipment for new energy materials, metallurgy, environmental protection, and fine chemicals. We are dedicated to delivering comprehensive, integrated services covering research and development, engineering design, equipment manufacturing, installation, and commissioning.

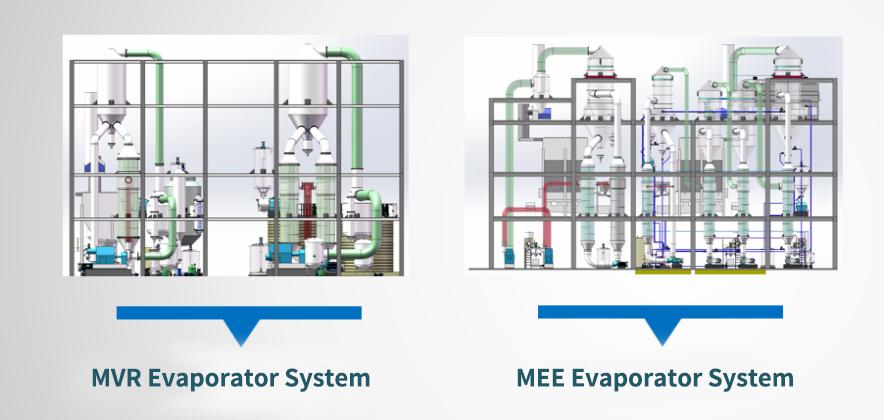

We offer specialized solutions including MVR (Mechanical Vapor Recompression) evaporation systems, TVR (Thermal Vapor Recompression) evaporation systems, MEE (Multiple-Effect Evaporation) systems, OSLO crystallization systems, and DTB (Draft Tube Baffle) crystallization systems.

Our production facility covers 12,000 square meters, staffed by over 50 skilled employees, including 10 senior technical experts. Backed by a strong collaboration with Universities and led by several renowned industry experts, we have developed a highly professional team skilled in design, fabrication, construction, and commissioning.

Over the years, we have accumulated extensive technical expertise and practical experience in various application areas, such as:

• Wastewater from lithium iron phosphate production

• Spent power lithium battery recycle

• Ternary precursor material processing

• Alunite and titanium metallurgy

• Saline chemical wastewater treatment

• Chemical and pharmaceutical manufacturing

• Biological fermentation processes

With years of continuous improvement and innovation, we have become a well-recognized equipment solution provider in the industry. We are committed to delivering reliable, high-performance turnkey projects, including process design, equipment supply, on-site installation, and commissioning—ensuring efficient, stable, and sustainable operations for our clients.

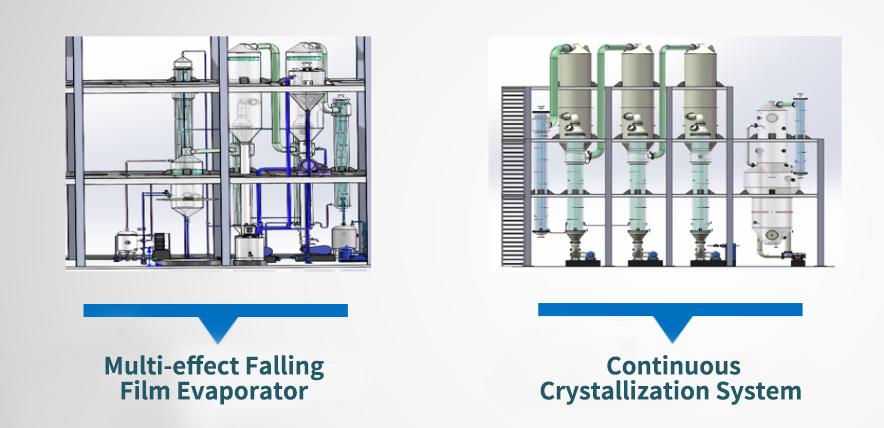

Product Range: We offer a comprehensive and versatile range of evaporation and crystallization systems, meticulously engineered to meet the diverse process requirements of our clients across various industries. Our product portfolio includes:

• MVR (Mechanical Vapor Recompression) evaporators: MVR technology utilizes mechanical energy to compress and elevate the temperature and pressure of vapor, significantly reducing the external energy required for evaporation and offering excellent energy efficiency;

• MEE (Multiple Effect Evaporators) : Our MEE systems maximize energy efficiency by using the vapor produced from one effect as the heating medium for the next. This staged approach minimizes steam consumption and provides a cost-effective evaporation solution for large-scale applications.

• Falling Film Evaporators: Engineered for high heat transfer efficiency, falling film evaporators allow liquid to flow as a thin film along the tube walls. Ideal for heat-sensitive materials, they deliver high evaporation rates with minimal thermal degradation.

• Forced Circulation Evaporators: Designed to handle highly viscous, scaling, or crystallizing liquids, our forced circulation evaporators use high-flow circulation pumps to ensure turbulent flow, preventing fouling and ensuring stable and efficient evaporation.

• Various crystallizers: We provide a range of advanced crystallizers, including OSLO crystallization systems, DTB (Draft Tube Baffle) crystallization systems, and other customized solutions tailored to meet the specific needs of various industries.

Contact US

Enchem is here to listen to your needs and provide sustainable solutions. Contact us to discover more.