Nickel sulfate (NiSO₄) is predominantly used in industry in the form of nickel sulfate hexahydrate (NiSO₄·6H₂O), appearing as bright green orthorhombic crystals and forming a weakly acidic aqueous solution. As a core nickel source for NCM/NCA ternary lithium-ion batteries, nickel sulfate enhances battery energy density and driving range, making it a fundamental chemical material for the lithium-ion new energy industry.

Nickel Sulfate Hexahydrate (NiSO₄·6H₂O) Crystallization

The crystallization of nickel sulfate hexahydrate (NiSO₄·6H₂O) is a key unit operation in the production of battery-grade nickel sulfate. The objective of this process is to convert purified nickel sulfate solution into solid NiSO₄·6H₂O crystals with controlled particle size, crystal morphology, and high purity, in order to meet downstream handling and product quality requirements.

Continuous vs Batch Crystallization

In industrial practice, NiSO₄·6H₂O crystallization is typically achieved by cooling crystallization, in which a hot, saturated nickel sulfate solution is gradually cooled to induce supersaturation and crystal formation. Depending on production capacity and product specifications, the process may be operated in either continuous or intermittent (batch) crystallization modes.

In industrial practice, NiSO₄·6H₂O crystallization is typically achieved by cooling crystallization, in which a hot, saturated nickel sulfate solution is gradually cooled to induce supersaturation and crystal formation. Depending on production capacity and product specifications, the process may be operated in either continuous or intermittent (batch) crystallization modes.

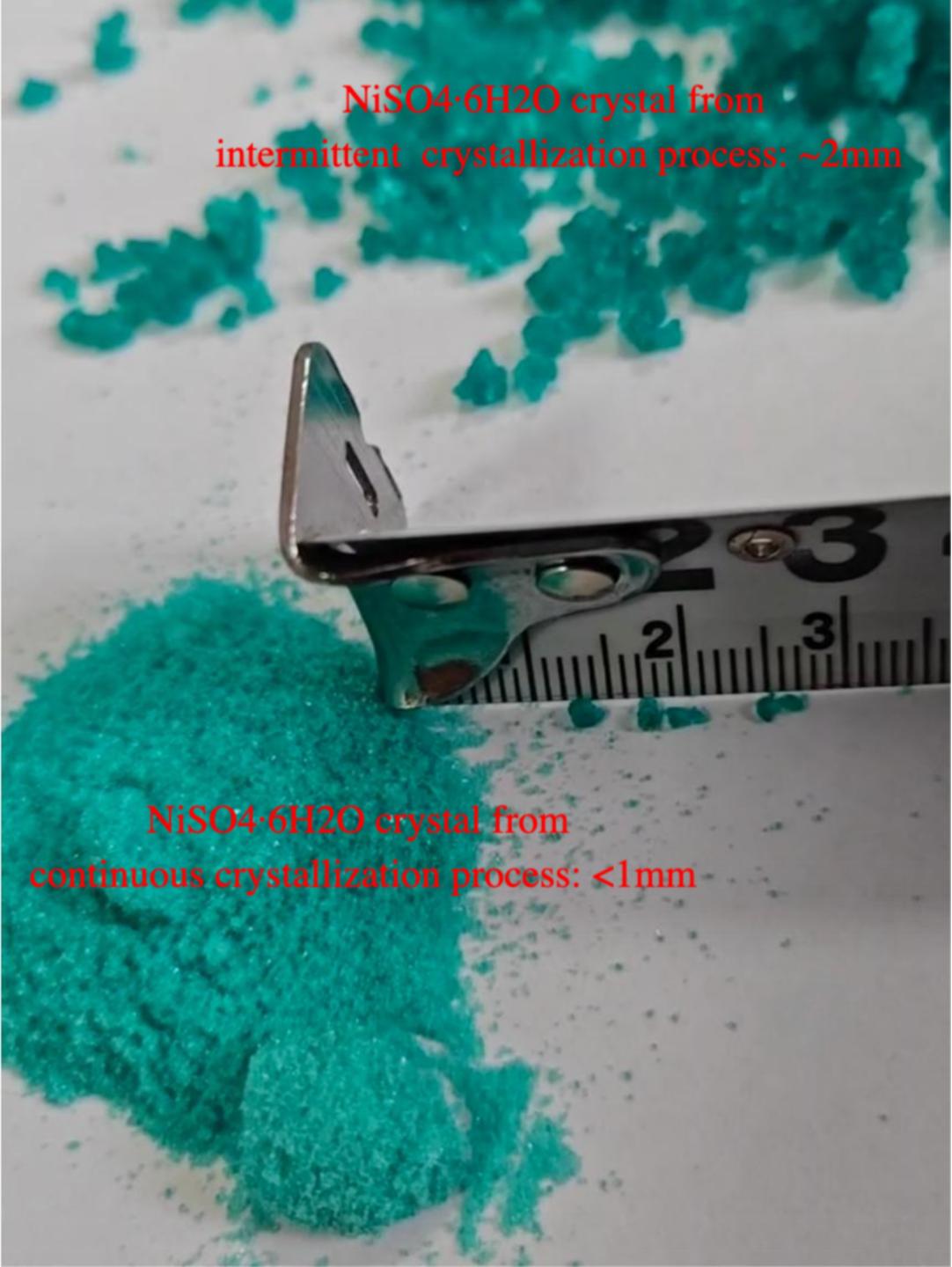

In a continuous crystallization process, the residence time and cooling duration are relatively short, which limits crystal growth. Consequently, the resulting NiSO₄·6H₂O crystals are fine, with particle sizes typically below 1 mm. This process operates continuously, requires a smaller equipment footprint, and is suitable for large-scale production.

In contrast, the intermittent (batch) crystallization process provides longer residence times and slower cooling conditions, allowing sufficient time for crystal growth. As a result, larger NiSO₄·6H₂O crystals, with typical particle sizes of approximately 2 mm, can be obtained. Although batch crystallization involves longer processing times and a greater number of crystallization vessels, it is advantageous when larger crystal size is required.

Our company has extensive experience in both continuous and intermittent (batch) crystallization of nickel sulfate hexahydrate (NiSO₄·6H₂O). We would be pleased to provide a tailored technical proposal upon request.

Get In Touch With US

Enchem is here to listen to your needs and provide sustainable solutions. Contact us to discover more.