Why Lithium Battery Recycling Matters

Lithium-ion batteries have become an essential part of daily life—from smartphones and laptops to electric vehicles and energy storage systems. While they provide convenience and efficiency, spent batteries pose significant environmental and resource risks. With battery usage rapidly increasing, the volume of end-of-life batteries is approaching a peak.

Standardized recycling and material recovery are not only an ecological responsibility but also a strategic approach to unlocking valuable resources. Efficient recycling helps protect the environment, recover critical metals, and supports the sustainable, green development of the energy sector.

Advanced Lithium Battery Recycling Process

Critical Role of Evaporation & Crystallization Equipment

The purified sulfate solutions obtained from extraction are typically too dilute to be used directly. Evaporation and crystallization systems play a critical role by concentrating these solutions and producing solid, battery-grade crystals:

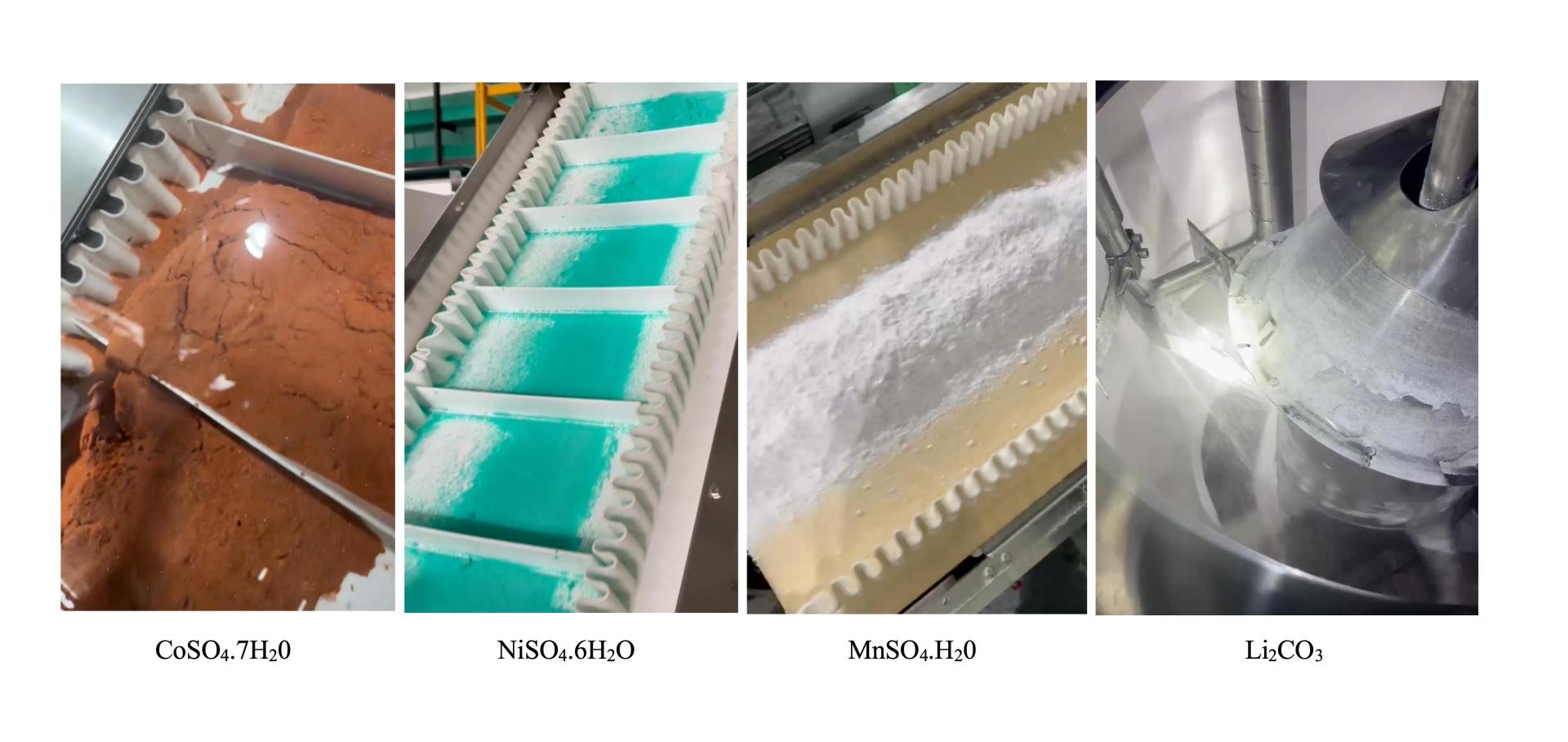

• Nickel sulfate crystals (NiSO₄·6H₂O): boosts energy density for NCM/NCA batteries

• Cobalt sulfate crystals (CoSO₄·7H₂O): enhances battery stability, safety, and cycle life

• Manganese sulfate crystals (MnSO₄·H₂O): reduces material costs while maintaining thermal and electrochemical performance

In addition, the condensate generated during evaporation process is fully recycled back into the upstream leaching process. This closed-loop water recovery improves energy efficiency and enhances the sustainability of the recycling process.

Technology Selection of Evaporation & Crystallization Equipment

The choice and design of evaporators are crucial for reducing energy consumption. High-efficiency evaporation technologies, such as multi-effect evaporators (MEE) and MVR evaporators, can significantly improve energy utilization:

• Multi-effect evaporators (MEE): Multiple evaporators are connected in series, allowing staged reuse of heat energy.

• MVR evaporators: Mechanical compression of secondary vapor generates high-temperature steam for reuse, further improving energy efficiency.

These technologies reduce operational energy consumption, minimize waste heat loss, and support sustainable production.

Key Considerations for Evaporator Design and Selection

Selecting the appropriate evaporator requires careful consideration of:

• Feed solution properties: composition, concentration, viscosity

• Processing scale and production capacity

• Energy efficiency and operational cost requirements

• Ease of operation and maintenance

• Environmental and emission standards

Optimizing evaporator design and operation ensures stable production, high product quality, and maximum energy efficiency for lithium battery recycling projects. By ensuring efficient concentration and crystallization, evaporation systems directly influence product quality, operational efficiency, and the environmental performance of lithium battery recycling projects, making them indispensable in modern battery material recovery.

Conclusion

Evaporation and crystallization systems are core equipment in lithium battery recycling plants. They:

• Convert diluted metal sulfate solutions into high-purity, battery-grade crystalline products

• Maximize energy efficiency through advanced evaporation technologies (MEE and MVR)

• Enable water recycling and environmentally sustainable operation

By ensuring efficient concentration and crystallization, evaporation systems directly influence product quality, operational efficiency, and the environmental performance of lithium battery recycling projects, making them indispensable in modern battery material recovery.

Get In Touch With US

Enchem is here to listen to your needs and provide sustainable solutions. Contact us to discover more.