Calcium chloride is a versatile product — from anhydrous granules to dihydrate flakes — but its high solubility, high boiling point elevation (BPE), and corrosive nature make the evaporation process challenging. The right process design and materials are critical for achieving efficient, reliable, and long-lasting operations.

Understanding the role of MVR

With the growing adoption of Mechanical Vapor Recompression (MVR) technology, its energy-saving potential makes it the preferred choice where energy costs are high.

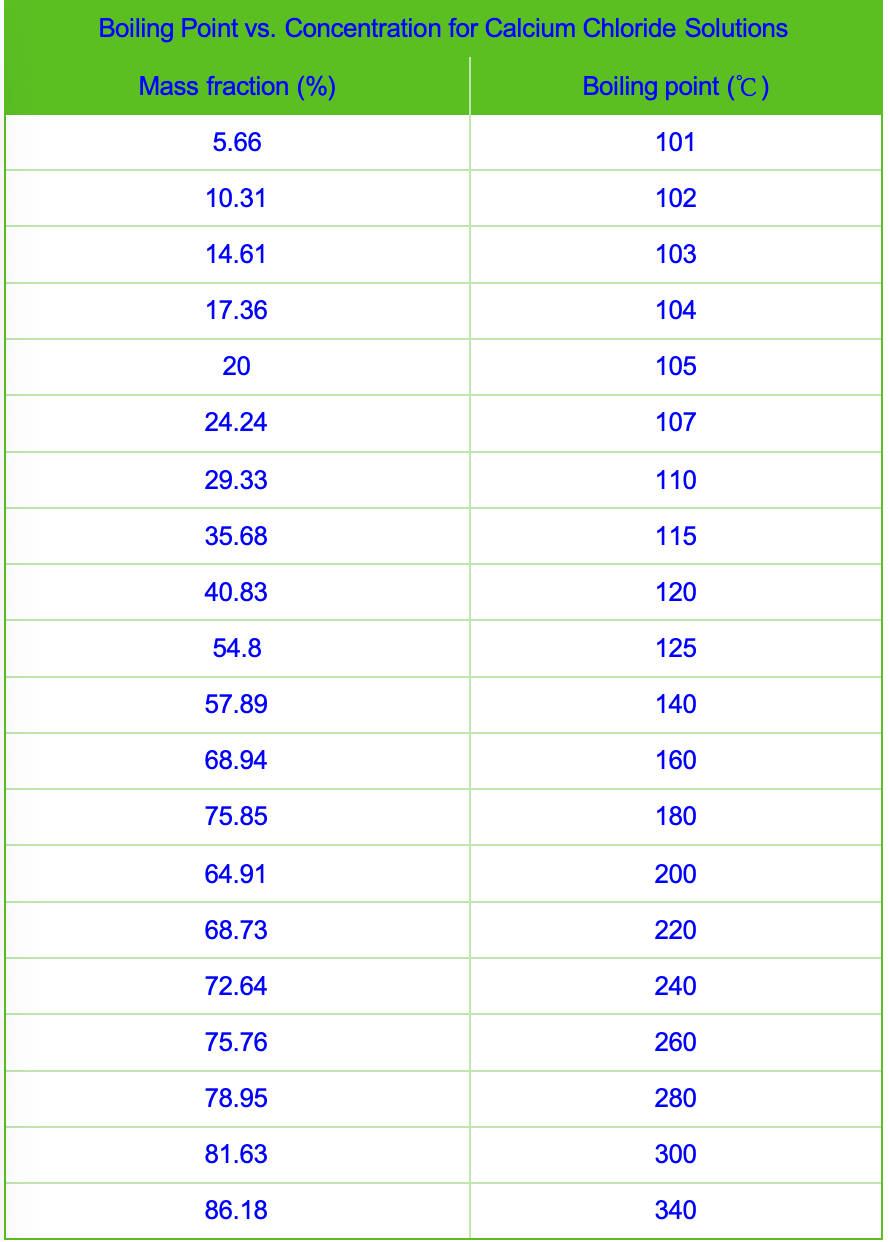

However, its suitability for calcium chloride concentration depends largely on the solution concentration:

Low to moderate concentrations (< 35%): MVR evaporator is highly efficient.

Higher concentrations (> 35%): The sharp rise in boiling point makes the temperature lift requirements steep. This could demand multiple compressors connecting in series, leading to higher power consumption and reducing the cost-saving benefits.

Recommended Process Strategy

|

Concentration range |

Recommend process |

Typical product |

| <5% →~ 35% | MVR evaporator- Efficient concentration with low energy use. | Feed for multi-effect evaporator stage |

| ~35% → ~50% | Multiple-Effect Evaporator – to reach ~50%, this concentration is ideal feedstock for spray granulation & fluidized-bed drying system to produce granule products | 94% Anhydrous CaCl₂ granules |

| ~50% → 68~70% | Multiple-Effect Evaporator + Single-Effect Finisher (high-pressure & high-temperature steam is needed as heat source to reach ~70%) –

The 68~70% CaCl₂ solution can be cooled and flaked to make calcium chloride dihydrate flakes, which are then dried in a fluidized-bed to get the final flake product. |

77% CaCl₂ dihydrate flakes |

Why Our Solutions Stand Out

Tailored Process Design: Whether you need granules or flakes, we design systems optimized for your production goals.

Energy-Efficient Operation : Integrating MVR evaporator and multiple-effect evaporator ensures the best balance between efficiency and performance.

Durable Materials: Equipment is built with carefully selected alloys to handle the corrosive properties of calcium chloride, tailored to different concentration and operating temperatures. This approach not only optimizes economic performance, but also ensures long-time, reliable operation while minimizing maintenance and downtime.

Get In Touch With US

Enchem is here to listen to your needs and provide sustainable solutions. Contact us to discover more.