Project Background

With the rapid expansion of the new energy sector, the volume of retired power batteries is increasing at an unprecedented pace, driving the emergence and growth of the battery recycling industry. This evolving field plays a vital role in promoting resource circularity and ensuring environmental sustainability.

Power lithium batteries are rich in valuable and strategic materials such as lithium, cobalt, and nickel. Improper handling of these resources can lead to significant environmental contamination and safety hazards. Implementing standardized and regulated recycling practices not only mitigates resource scarcity but also contributes to the broader development of a circular economy.

Through advanced recycling technologies, battery-grade compounds such as cobalt sulfate, lithium sulfate, nickel sulfate, manganese sulfate, and lithium carbonate can be efficiently recovered. Among the key processing stages, evaporation and crystallization are critical for producing high-purity materials essential to battery performance.

The technological advancement, operational stability, and process reliability of evaporation and crystallization systems directly affect the quality of recovered battery materials, which in turn determine the efficiency, safety, and lifespan of next-generation lithium batteries.

Among available technologies, Mechanical Vapor Recompression (MVR) evaporators have emerged as a preferred solution for battery recycling projects, thanks to their exceptional energy efficiency and low operating costs, while meeting the stringent requirements for product purity and sustainability.

Hydrometallurgical Process in Power Battery Recycling

Among the various recycling approaches, the hydrometallurgical process is currently the most mature and widely implemented method for lithium-ion battery recovery.

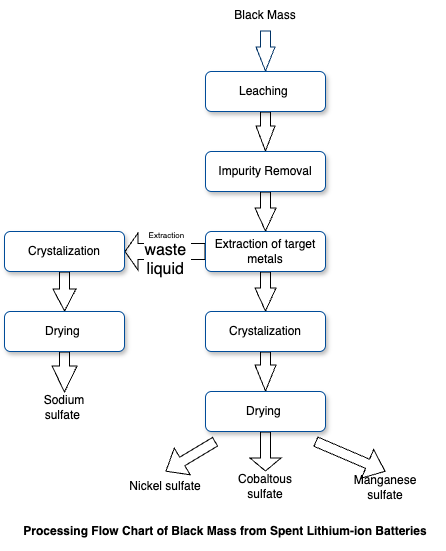

In this process, spent batteries are first subjected to crushing and physical separation to extract active materials, commonly referred to as black mass. These materials are then processed through multi-stage leaching and continuous counter-current solvent extraction, producing purified solutions of nickel sulfate, cobalt sulfate, and manganese sulfate.

The resulting metal-rich solutions are subsequently treated using evaporation, crystallization, and drying technologies—most effectively achieved through MVR evaporators—to produce high-purity battery-grade metal salts. These salts serve as critical feedstocks for synthesizing ternary precursor materials (NCM), thereby completing the value chain from retired batteries to new battery materials.

MVR Evaporator: Core Equipment for Efficient Crystallization

In the hydrometallurgical battery recycling line, the evaporation and crystallization stage is essential for achieving both product purity and recovered water reuse. Among all available options, the Mechanical Vapor Recompression (MVR) evaporator is recognized as the most efficient and reliable solution.

Key Advantages of MVR in Battery Recycling:

1) Energy Efficiency:

MVR evaporator recycles and compresses secondary vapor generated during evaporation using a mechanical compressor, drastically reducing the need for fresh steam and cutting operational energy costs.

2) Stable and Continuous Operation:

MVR evaporators are ideal for handling large volumes of metal salt solutions such as NiSO₄, CoSO₄, and MnSO₄, ensuring uniform concentration and controlled crystallization under stable conditions.

3) Intelligent Monitoring and Control:

Advanced instrumentation enables real-time monitoring of condensate quality, liquid levels, and system performance, allowing for self-cleaning and fault diagnostics, which enhance reliability and reduce downtime.

Reference Project: MVR Evaporators in Lithium Battery Recycling

Our company contributed to a lithium battery recycling project by supplying multiple MVR evaporator systems, customized for different process streams. The equipment supplied included:

• MVR Evaporator for Sodium sulfate concentration:with evaporation capacity @ 38 tons/hour;

•MVR Evaporator for Sodium chloride crystallization: with evaporation capacity @ 3 tons/hour;

•MVR Evaporator for Nickel sulfate crystallization: with evaporation capacity @ 4 tons/hour;

•MVR Evaporator for Cobalt sulfate crystallization: with evaporation capacity@ 1.2 tons/hour;

•MVR Evaporator for Manganese sulfate crystallization: with evaporation capacity@ 1.6 tons/hour;

The project has been successfully commissioned and is now in stable operation. Over time, the MVR systems have demonstrated excellent energy-saving performance and reliable long-term stability, affirming their value in high-demand recycling environments.

Get In Touch With US

Enchem is here to listen to your needs and provide sustainable solutions. Contact us to discover more.