Definition Of Industrial Wastewater

Industrial water refers to wastewater, sewage, waste liquids, or aqueous solutions of primary or by-product materials generated during industrial production processes. Common examples include: Sodium chloride, ammonium chloride, potassium chloride, barium chloride, calcium chloride, sodium sulfate, potassium sulfate, lithium sulfate, cobalt sulfate, manganese sulfate, nickel sulfate, ammonium sulfate, sodium hydroxide, sodium thiocyanate, humic acid black liquor, landfill leachate, black and yellow liquor from papermaking, amino acids, xylose, erythritol, fruit acids, organic acids, citric acid, and etc.

Classification Of Industrial Wastewater

1. By Chemical Composition of Major Constituents

Industrial water can be categorized based on the chemical nature of its primary contents into:

• Organic industrial water, which primarily contains organic substances, and

• Inorganic industrial water, which is dominated by inorganic compounds.

In many cases, industrial water may contain a mixture of both.

Examples include:

• Inorganic water: Wastewater from electroplating and mineral processing.

• Organic water: Wastewater from food processing and biological fermentation.

2.By Industry Type or Production Process

Industrial water can also be classified according to the nature of the industrial enterprise or the materials being processed. Categories include:

• Food processing

• New energy industries

• Fermentation

• Pharmaceuticals

• Starch sugar production

• Pulp and paper (papermaking)

• Textiles

• Leather processing

• Pesticide manufacturing

• Metallurgy

• Petroleum refining

3. By Type of Pollutants Present

Classification based on the dominant pollutants in industrial water includes:

• Non-polluted industrial water

• Acidic wastewater

• Phenolic wastewater

• Heavy metal wastewater

• Organophosphorus wastewater

Zero Liquid Discharge (ZLD)

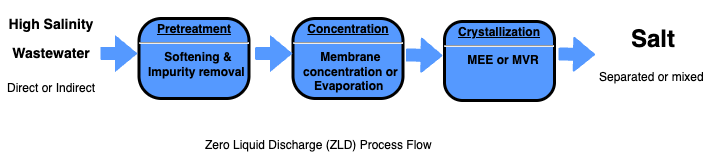

Zero Liquid Discharge (ZLD) is an environmental technology concept and process objective primarily applied in the treatment of industrial wastewater. Its core principle involves separating water and contaminants through a series of advanced treatment steps, ultimately achieving complete elimination of liquid discharge. The process results only in the generation of solid waste (such as salts and sludge), thereby minimizing environmental pollution to the greatest extent possible.

Evaporation crystallization is positioned at the final stage of industrial wastewater treatment, where the wastewater is further concentrated and converted into solid waste, such as crystalline salts and sludge cakes, thereby achieving Zero Liquid Discharge (ZLD). Technologies such as Multi-Effect Evaporator (MEE) and Mechanical Vapor Recompression (MVR) are commonly employed. These methods are particularly suitable for treating high-salinity wastewater streams, including desulfurization wastewater and concentrated chemical brines.

Contact US

Feel free to contact us for customized solutions and competitive offers in evaporation and crystallization systems.