Technical background of MVR evaporator

Evaporation, distillation, evaporation-crystallization, and evaporation-drying systems are all known for their high energy consumption. Energy usage accounts for a significant portion of the operating costs for these types of equipment. Therefore, reducing and optimizing specific energy consumption is a critical strategy for lowering overall operational expenses.

To address this challenge, there are three main technologies commonly used to minimize energy consumption. These technologies can be implemented independently or combined, depending on process requirements:

• Multiple-Effect Evaporation (MEE)

This method reuses the vapor from one effect as the heating medium for the next, reducing steam consumption across multiple stages.

• Thermal Vapor Recompression (TVR)

TVR systems utilize steam ejectors to recompress a portion of the vapor, increasing its temperature and allowing it to be reused as a heat source.

• Mechanical Vapor Recompression (MVR)

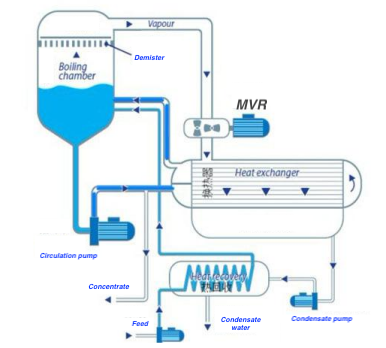

MVR systems mechanically compress the secondary vapor generated during evaporation to elevate its temperature, pressure and enthalpy, enabling it to be reused as a heating medium in the heat exchanger for incoming feed material.

Among these technologies, MVR technology offer the lowest energy consumption, making them the most energy-efficient solution for many industrial applications. By leveraging mechanical energy rather than thermal input, MVR systems significantly reduce external steam demand and provide a more sustainable and cost-effective approach to evaporation.

MVR: A High-Efficiency, Energy-Saving Evaporation Technology

Mechanical Vapor Recompression (MVR technology) is an advanced energy-saving technology that recycles the energy from its own secondary steam, significantly reducing the need for external energy sources such as fresh steam.

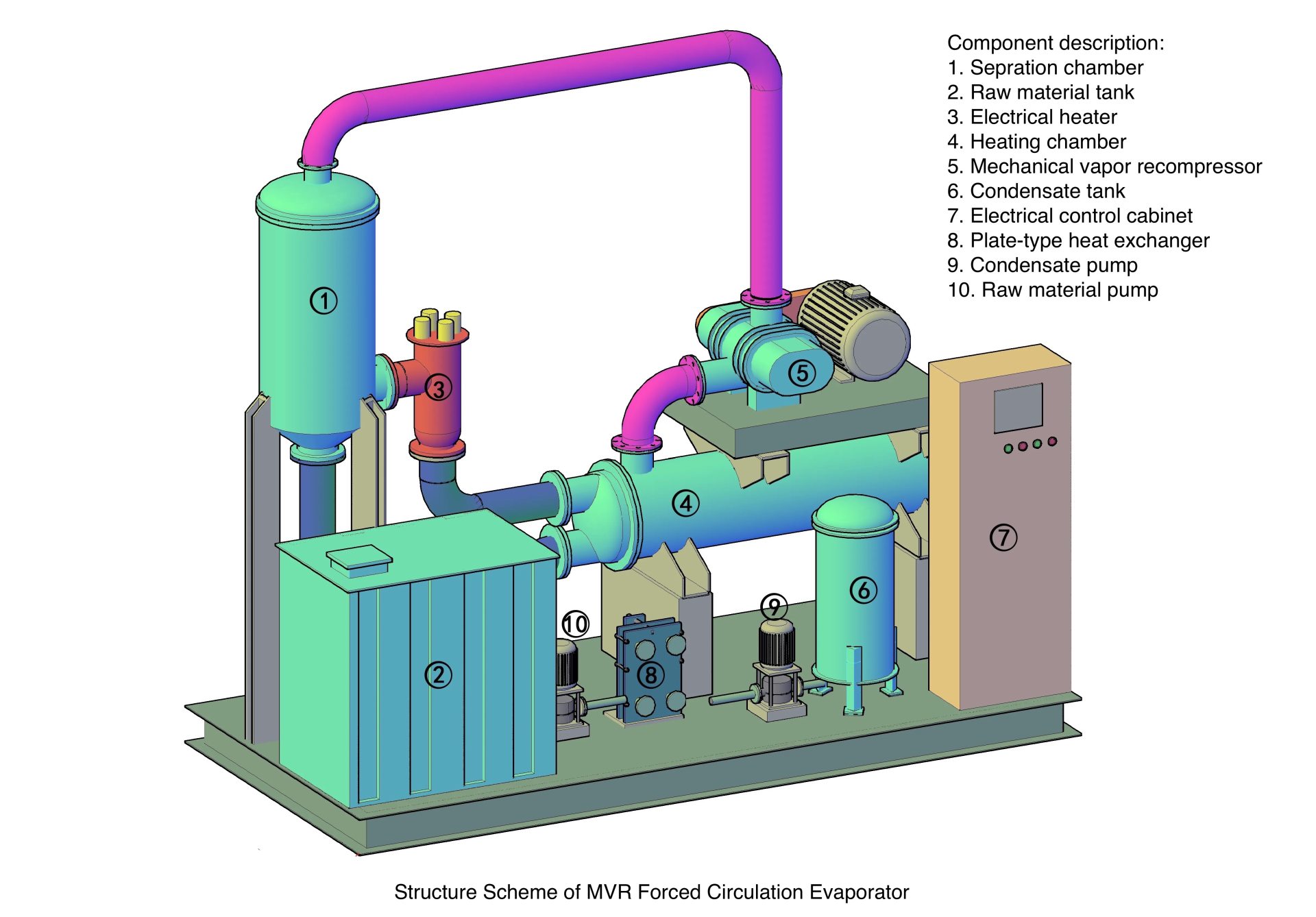

In an MVR evaporator, the low-temperature secondary vapor generated during the evaporation process is compressed by a compressor. This compression increases the vapor’s temperature, pressure, and enthalpy, transforming it into a high-grade heating medium. The compressed vapor is then directed back into the evaporator’s heating chamber, where it provides the thermal energy required to keep the feed liquid boiling. During this process, the heating vapor condenses into condensate, and the previously discarded secondary steam is fully reused. This efficient recovery of latent heat greatly enhances thermal efficiency. In fact, the steam economy of an MVR evaporator is equivalent to that of a traditional 30-effect evaporator.

Applications of MVR Technology

MVR (Mechanical Vapor Recompression) technology is widely applied across various industries that require efficient and continuous evaporation. Thanks to its low energy consumption, compact design, and high thermal efficiency, MVR has become a preferred solution in both environmental and industrial processing fields.

• Chemical Industry

Concentration of chemical solutions such as sodium sulfate, ammonium chloride, and phosphoric acid

Recovery of solvents and valuable components

Crystallization of salts from brine or process liquors

• Pharmaceutical Industry

Concentration of pharmaceutical intermediates and APIs

Treatment of high-COD wastewater from drug production

Recovery of heat-sensitive compounds using low-temperature MVR systems

• Food and Beverage Industry

Concentration of juices, dairy products (e.g., whey, milk), and liquid sweeteners

Production of extracts and flavorings

• New Energy Materials

Concentration and purification processes in lithium carbonate, lithium hydroxide, and ternary precursor production

Treatment of lithium iron phosphate (LFP) and nickel-cobalt-manganese (NCM) production wastewater

• Metallurgical Industry

Evaporation and crystallization of metal salt solutions

Zero Liquid Discharge (ZLD) applications in hydrometallurgy

Concentration of acidic or alkaline leachates

• Environmental Protection

High-salinity wastewater treatment from chemical and textile plants

Leachate treatment in solid waste management and landfills

Zero Liquid Discharge (ZLD) systems to comply with environmental regulations

• Bio-Fermentation and Biotechnology

Concentration of fermentation broths

Recovery of organic acids, amino acids, and enzymes

Efficient handling of heat-sensitive biological liquids

• Solvent Recovery

MVR technology is also effectively applied in the recovery of organic solvents—such as ethanol, methanol, and isopropanol—used in extraction and purification processes across the chemical, pharmaceutical, and biotechnology industries.

Contact US

Enchem is here to listen to your needs and provide sustainable solutions. Contact us to discover more