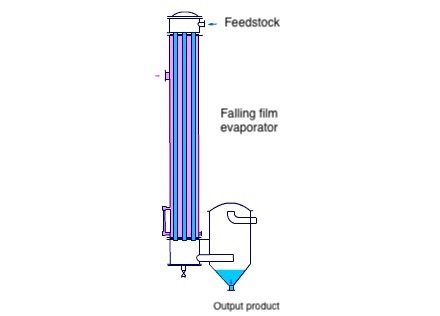

Falling-Film Evaporator

The falling film evaporator stands out for its efficiency and gentle handling of heat-sensitive products, is suitable for solutions such as milk, glucose, oligosaccharides, sorbitol, fruit and vegetable juice, etc. It is widely used in the evaporation and concentration of aqueous solutions and organic solvent solutions in industries such as food processing, pharmaceuticals, deep processing of grain, bioengineering, environmental engineering, and etc.