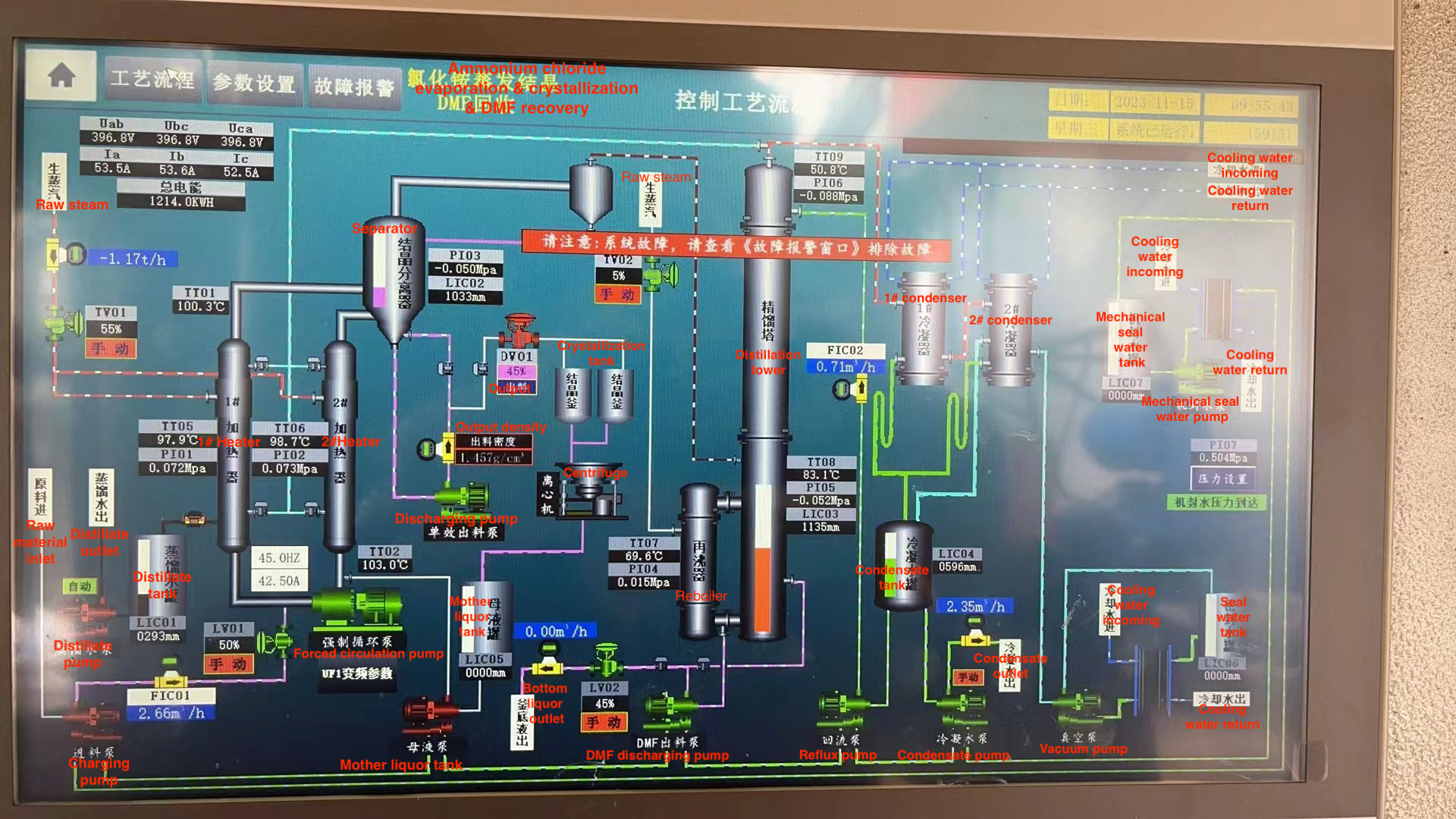

Ammonium Chloride Evaporation & Crystallization Project Completed with DMF Distillation

An ammonium chloride evaporation and crystallization project, completed with distillation of DMF, obtaining ammonium chloride crystals and high-purity 99% DMF from ammonium chloride solution:

1.Input material: ammonium chloride solution with ammonium chloride content @20%, and contains 8% DMF.

2.Input capacity: 5500kg/hr;

3.Output capacity: ammonium chloride crystals 1000kg/hr;

4.Treatment subject: obtaining ammonium chloride solids and recovering high-purity 99% DMF.